Biomass Pellet Production Line

Application

The biomass pellet production line can used for wood chips, sawdust, bamboo shavings, wood shavings, wood shavings, barley straw, oat straw, wheat straw, rye, straw, rice straw, sorghum straw, stalk and corn straw, and potato vines, etc.

1. Widely used in households, farming and industries.

2. Mainly suitable for producing feed pellets, fuel pellets, fertilizer pellets,etc.

3. Applied to different grains such as corn, wheat, sorghum, and any type of agro-forestry waste

crops straw, husks, vines, wood chips, etc. (Energy-saving & Environment-protecting)

4. As for the power, you can choose diesel engine driven or electric motor driven.

And we have many models with different output; they can meet different required capacity.

5. Size range of making wood pellets: Φ6, Φ8, Φ10, Φ12mm

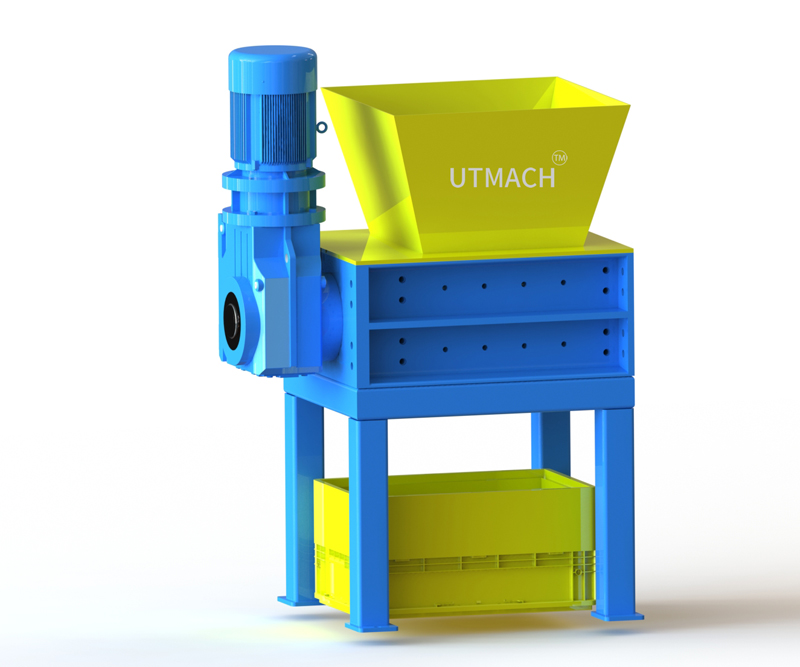

Biomass Pellet Production Line

1. Crushing and broken system. If the raw material is the log, straw, leftover material and something bigger, needed to crush raw materials before pelleting.

2. Drying system. In general, the material with the moisture of 15-20% is suitable for granulating If more than 20%, needed to dry before granulating.

3. Granulating system. The final moisture of the pellet meets the safe store requirements of the pellet.

4. Cooling screening system. Biomass pellet after cooling screening machine go through belt conveyor into cooling sieve.

5. Packaging system. Send the biomass pellet into in packaging machine.

Features of wood sawdust pellet mill:

1. The flat die wood pellet mill are easier to be cleaned than ring die pellet mill.

2. Easy to change die and roller faster and easily.

3. Small size and lightweight, making small-scale production possible.

4. It is possible to view into the chamber when pelletizing, so you can solve any problem in time.

Position :

Position :