Oil Sludge Treatment Line

Oil Sludge Crushing & Sorting Processing System

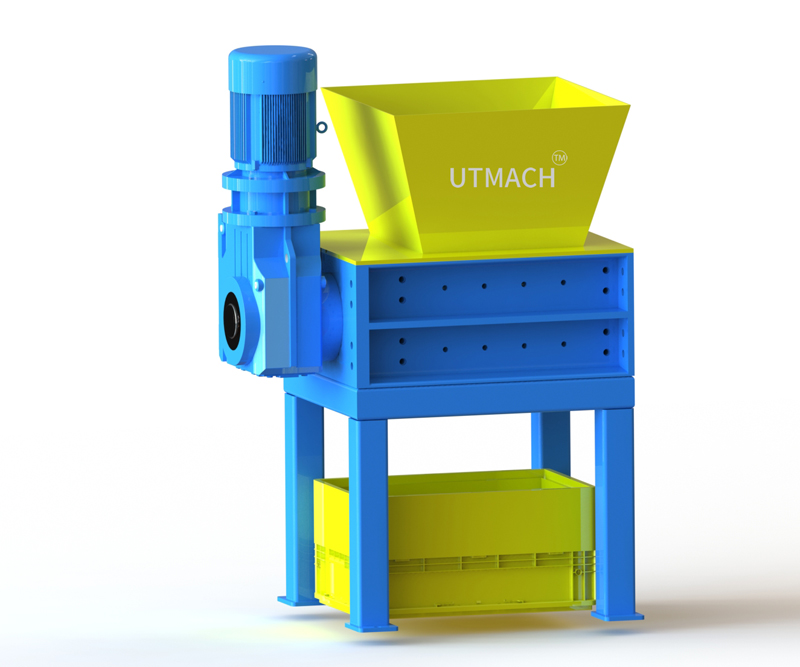

Oily sludge is oily solid waste produced in the process of oil exploitation, transportation, refining and disposal of oily sludge. Sludge in general oil content in 10 ~ 50%, water content in 40 ~ 90%. Crushing is an indispensable part in the treatment and disposal of oily sludge. The crusher from United Tech Machinery can crush the large oily sludge and its package into small materials, which is more convenient for subsequent landfill, incineration, degradation or other treatment operations.

The oil sludge recycling treatment system of United Tech machinery is the method of crushing the sludge and its packaging first, and then sorting the materials. This treatment has the advantages of low cost, simple operation and not easy to cause secondary pollution.

The Oil Sludge crushing & sorting processing system from United Tech is use the physical differences of the composted materials, including disassemble, crush, sorting, etc. After sorting, the materials like metal, plastic, glass, is separated. This method is simple.

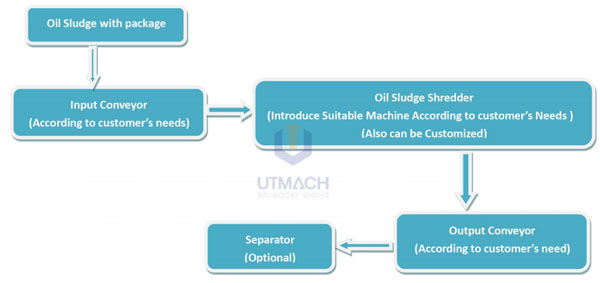

The Oil Sludge processing diagram:

Description:

This processing diagram is used for the Oil Sludge crushing and sorting. It can be adjusted according to customers’ actual condition.

After shredding, sort out the materials like plastic, sand, etc, and liquid material.

Features:

The oil sludge processing system is totally enclosed design, including crushing, convey, sorting, etc.

The core shredder with the welding alloy steel, strong wear resistance, decrease the maintenance cost.

The blade is detachable design, spiral arrangement, easier to catch the materials to crush.

Brand plate speed reducer, low speed, large torque.

United Tech take the “ crush, reduce, sort, recycling” as the principle, and prodcue the processing system according to the exact condition and the final purpose. United Tech Machinery, one professional crushing expert to meet your requirements to the CUSTOMIZED SHREDDER.

Position :

Position :