Separating Solid Waste Material

For selecting solid waste is to separate the recoverable or unfavourable particles from the process requirements of subsequent treatment and disposal.

This is one of the important treatment links in the solid waste treatment process after crushing.

According to the physical and physicochemical properties of waste, there are mainly the following separation methods: screening, gravity separation, magnetic separation, electrostatic separation, photoelectric separation, eddy current separation and flotation separation.

(1) Screening.

Screening, also known as screening, is the use of different particle size distribution of solid materials, smaller than the sieve through the sieve of fine materials, and larger than the sieve of coarse materials on the screen, to complete the process of separation of coarse and fine materials.

The factors affecting the screening efficiency include vibration mode, vibration frequency, vibration direction, sieve Angle, difference in particle recoilability, number of sieve holes and percentage of particles with similar sieve hole size in total particles.

Screen is equipped with fixed screen, vibrating screen and roller screen, etc.

They are usually assembled or used in series with other sorting equipment.

Screening technology is widely used in the recovery and utilization of solid waste resources.

(2) Gravity sorting.

Gravity separation is a method of separation based on the density difference of mixed solid waste in the medium.

In the same moving medium, solid waste particles with different densities are loosely stratified and separated due to the joint action of gravity, medium dynamics and mechanical forces, so that products with different densities are obtained.

Solid particles can be sorted only in a moving medium.

Gravity separation medium may be air, water, or heavy liquid (liquid with a density greater than that of water) and heavy suspension (composed of dense solid particles and water), etc.

(3) Magnetic separation.

Magnetic separation technology is a method of separation of ferromagnetic materials by means of magnetic field generated by magnetic separation equipment.

Solid waste including different kinds of magnetic components, when these different magnetic component material by magnetic field, due to the magnetic differences, magnetic effect each other is not the same, strong magnetic particles will be brought to a non-magnetic area and off, weak magnetic or non-magnetic particles, only by the effect of its own gravity and centrifugal force falls to scheduled another non-magnetic zone, thus completing the process of magnetic separation.

Magnetic separation of solid wastes is mainly used to recover or concentrate ferrous metals (ferrous substances) from solid wastes.

Solid waste with different magnetic components can be selected by magnetic separation equipment with different magnetic intensity.

Solid waste magnetic separation equipment according to the different ways of feeding, can be divided into belt magnetic separation machine and roller type magnetic separation machine two categories.

(4) Electrostatic separation.

Electrostatic separation technology is a method of material separation based on the difference of electrical conductivity, thermoelectric effect and electrification effect of various substances.

It can be used for sorting various materials such as plastic, rubber and fiber paper, synthetic leather, film, glass and metal.

For example, applying a voltage to a mixture of two different properties of plastic, making one plastic negatively charged and the other positively charged, would allow the two to separate.

(5) Vortex current separation.

Eddy current separation is a separation technique in which non-magnetic conductive metals (such as steel, aluminum, zinc, etc.) are separated from solid waste.

When a stream of solid waste containing non-magnetic conductive metals passes through an alternating magnetic field at a certain speed, the inside of these non-magnetic conductive metals induces eddy currents and creates an electromagnetic repulsion for the metal blocks that produce eddy currents.

The electromagnetic repulsion force on the metal depends on the metal resistivity, magnetic permeability, magnetic field density change speed and the shape and size of the metal block, so this principle can be used to separate some non-ferrous metals from the mixed waste.

(6) Flotation.

Flotation is to add flotation agents into the slurry modulated by solid waste and water, and through the air to form numerous small bubbles, so that the particles of the material to be selected adhere to the bubbles, float on the surface of the slurry with the bubbles to become a foam layer, and then scrape out for recovery.

The non-floating particles will remain in the slurry and be discarded after proper treatment.

The flotation of solid waste is mainly based on the selectivity of the material to be selected for bubble adhesion.

Some of them are hydrophobic surface, easy to adhere to the bubble, while others are hydrophilic surface, not easy to adhere to the bubble.

The hydrophilic and hydrophobic properties of the material surface can be enhanced by flotation agents.

Therefore, proper selection and use of flotation reagents in flotation process is the main external factor to adjust the flotability of substances.

In China, flotation has been used to recover carbon from fly ash, pyrite from coal gangue and metal from incinerator ash.

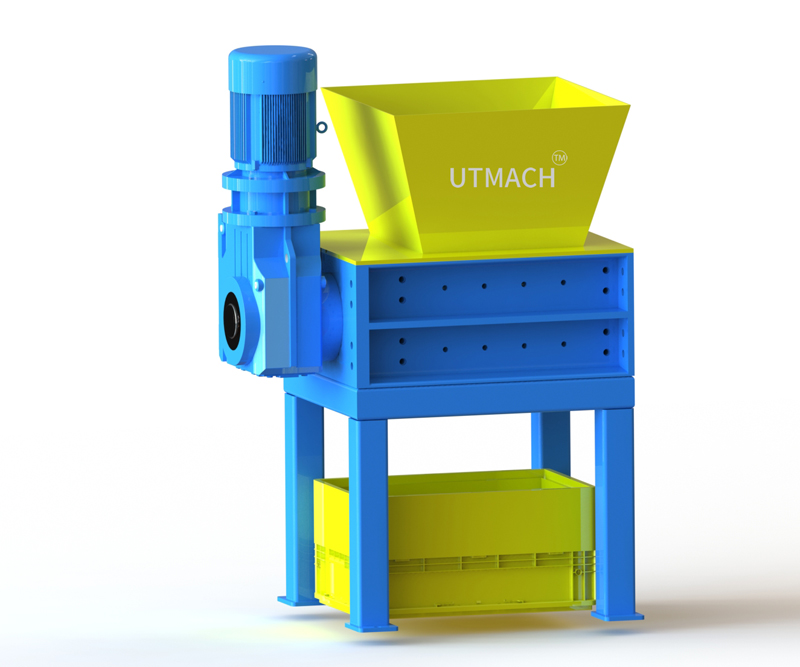

Waste Materials Trial Shredding:

Welcome you to send us your solid waste materials to have a trial shredding. We can post you the shredded materials, and provide the shredding videos for your kindly reference. So you can get a clear knowledge to our machine and its effect in home.

Please feel free to contact us when your needs more information about our United Tech shredders and scrap recycling equipment. We are dedicated to supplying durable machines with very competitive price.

Position :

Position :