Stainless steel reactor is widely used in chemical, food, coating, hot melt adhesive, silica gel, paint, medicine, petrochemical production of reaction, evaporation, synthesis, polymerization, saponification, suffocation, chlorination, nitrification and other processes of pressure vessels, such as reactor, reaction kettle, decomposition pot, polymerization kettle and so on. Reaction pot is mainly composed of inner tank, jacket, stirring device, supporting seat four parts (according to the process needs to adopt thermal insulation structure).

The inner tank body is made of stainless steel (SUS304, SUS316L or SUS321) and other materials according to the process needs. The inner surface is treated with mirror polishing. It can be cleaned CIP and sterilized SIP online, which meets the requirements of health regulations.

The jacket is made of stainless steel (SUS304) or carbon steel (Q235-B).

Suitable diameter to height ratio design, according to the need to customize the mixing device; The stirring shaft seal adopts pressure-resistant sanitary mechanical seal device to maintain the working pressure in the tank and prevent the material leakage in the tank from causing unnecessary pollution and material loss.

Support type according to the operation requirements of the suspension ear type or floor leg type.

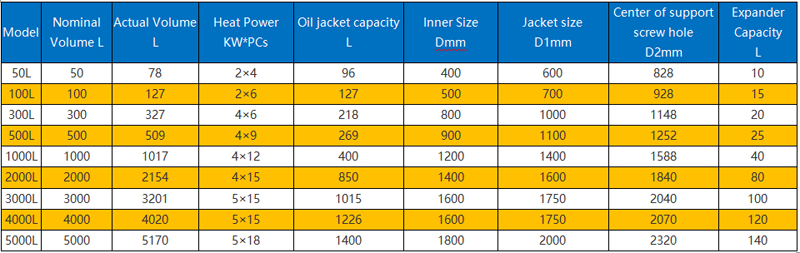

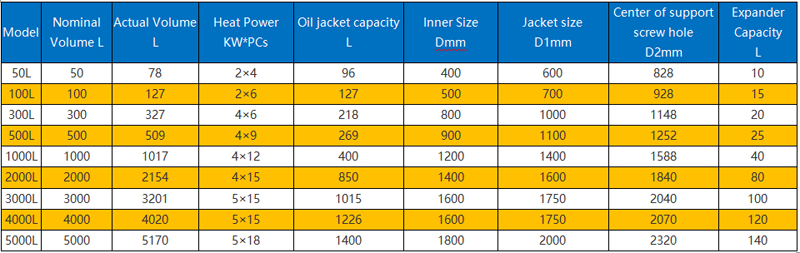

Technical reference of stainless steel reactor

Note:

The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support