Hammer Crusher

When the material enter into the crusher, it is crushed under the high-speed rotating ring hammer driven by the motor, while the crushed material obtained the kinetic energy rushing to the impact plate for the second crushing process before falling on the screen plate where it is cut,extruded,and grinded by the ring hammer and crushed under the interaction between the material and be discharged from the screen holes. The material that can't be crushed get into the metal collector to be eliminated regularly.

Hammer Crusher is suitable to crush all kinds of brittle materials,like coal,coal ore,coke,slag,red sandstone,shale,loose limestone,etc.

This Crusher is widely used in mining, cement, coal, metalgully, construction, roadway, etc industries.

The grid size is adjustable, controllable particle size, particle shape better.

Hammer crusher:

1. description: PC crushers were developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and Petroleum & Chemical industries.The capacity of our hammer crusher varies from 8~80 t/h. And the weight of our hammer crusher varies from 0.8~6.5 ton.

2. working principle: PC crusher is composed of machine box, rotor, hammer, impacting lining board and screen board. According to the requirement of the customers, this equipment can adjust the gap between the grating bars to change the discharging granularity. PC crusher crushes material by impacting it against a rotating hammer, by the collisions between high-speed hammer and material.Then the material is forced against a rugged solid plate called a "breaker plate" which further degrades the particle size. Finally, the material is forced over a discharge grate by the hammers.

3. Features:

(1). Compact structure, easy maintenance

(2). High wear-resistant hammerhead

(3). Small investment, big returns

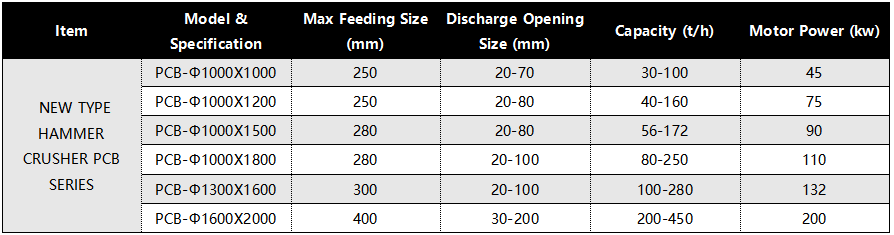

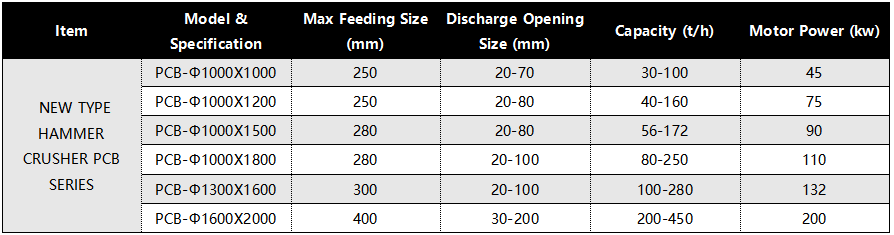

New Type Hammer Crusher PCB Series

Note:

1. The voltage about the power supply can be selected by the customer’s specific requirements.

2. The crusher capacity can be influenced by the material composition and output size.

The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support

What service do you need? Debugging and technical support